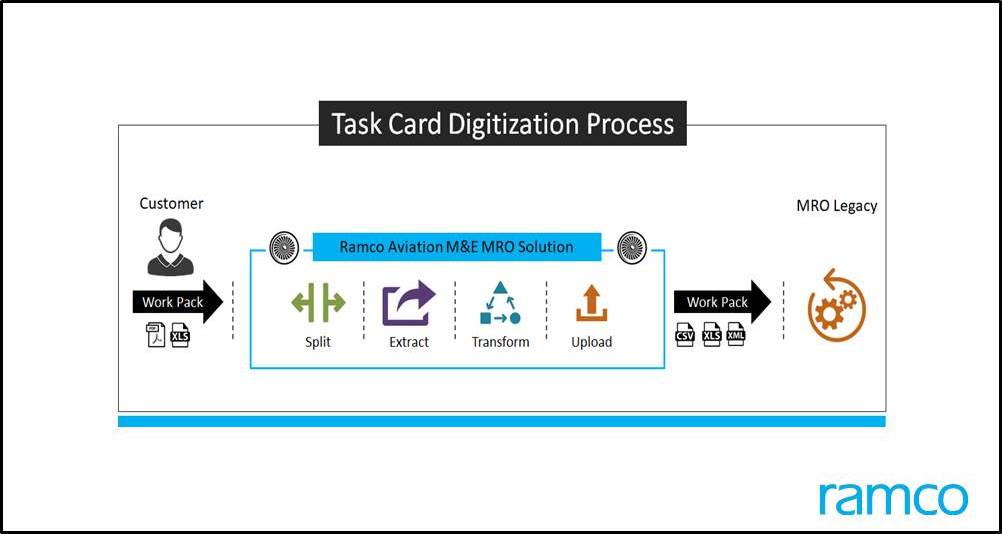

4-Step process to digitize PDF-based MRO Work package & Task Cards

Published :

If you are a 3rd party MRO service provider, chances are that most of your airline customers will supply the work package in PDF format. It is quite likely that you will receive the package 1 or 2 weeks before the aircraft’s arrival. Now, you will be dealing with varying package content types and formats as this is generated from the airline operator’s respective MRO systems.

What lies ahead of you are long hours or even days of manual process of the following activities:

Thanks to the software tools and platforms available today, most (if not all) of the above-mentioned processes can be automated. It may not be as complex or expensive as you may think. So, read on and see how you can leverage the four steps to digitize PDF-based MRO task cards of your customers.

As a 3rd party MRO aviation service provider, you need to adapt to varying package structures and content formats that will be provided by an aircraft operator.. The simplest of all is when the airline provides you with a tally or summary sheet in .XLS format (which can be directly imported into the MRO system) and it is also convenient when they share aviation task cards that are already split at the customer task card level. As the task card is already split, automation will be required only to attach the task cards to respective tasks by matching the task number reference.

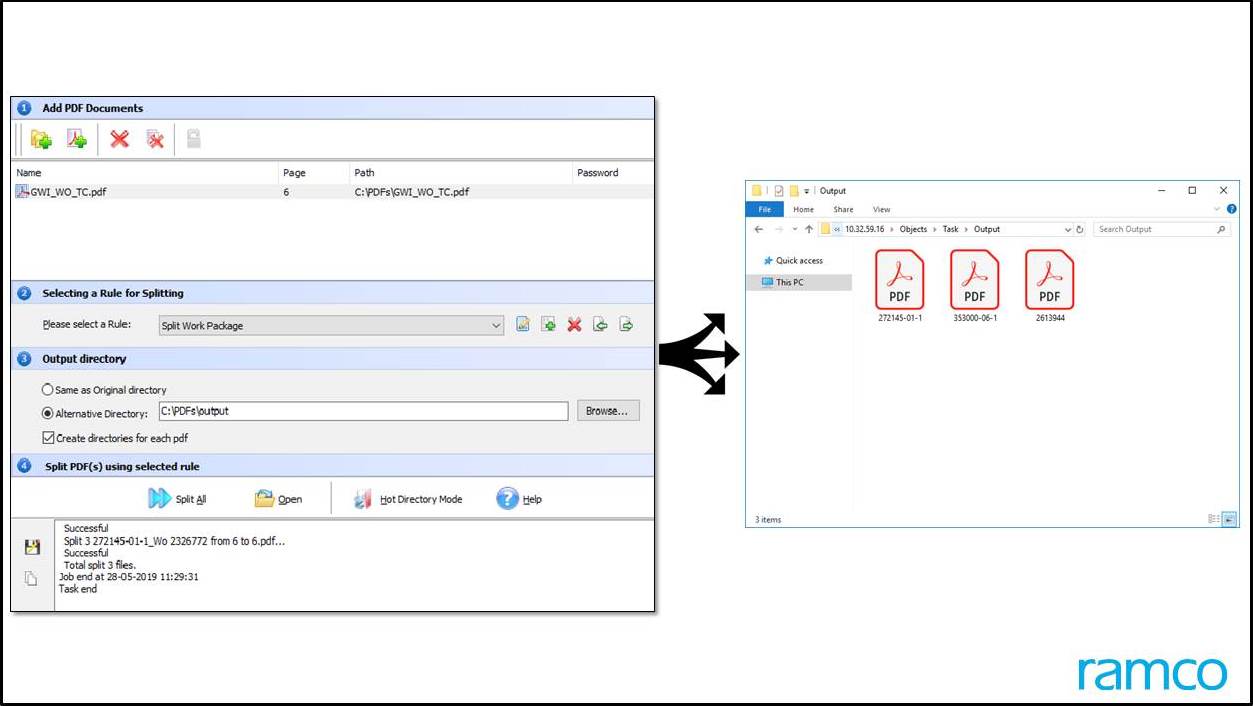

If you get only the tally sheet in .XLS and the rest of the package (job and task cards) in the form of consolidated PDF, it will be time-consuming to manage the process manually. The split process automates splitting of the consolidated files into multiple files at the level of individual task cards.

To manage everything efficiently, set up a custom template structure and identify the data item to be used as a reference to split. The most used split identifier is MPD (Maintenance Planning Document) task number. Whenever this number changes in the PDF, the split is performed. You might need to define the split rules based on bookmarks, keywords, and page numbers to manage the variation in template forms across MPD, EO (Engineering Orders) /SB (Service Bulletin), Deferred Items, Access Panel, and Hard time task cards.

With the help of a user-friendly interface to set up the rules and platforms like python libraries, the split process tremendously reduces the time to process. The split files are stored in SFTP/FTP location (can be shared with legacy MRO systems) and the naming convention for the split files can also be configured. For example, split identifiers like customer task number or AMM task number are normally configured as default file names.

The key to audit the split process is to compare the input tags/tally sheets with the output files. However, manual intervention is needed when dealing with scanned PDF or any exceptions concerning formats due to which the split can fail.

Also Read: How can Aviation MRO efficiency be improved?

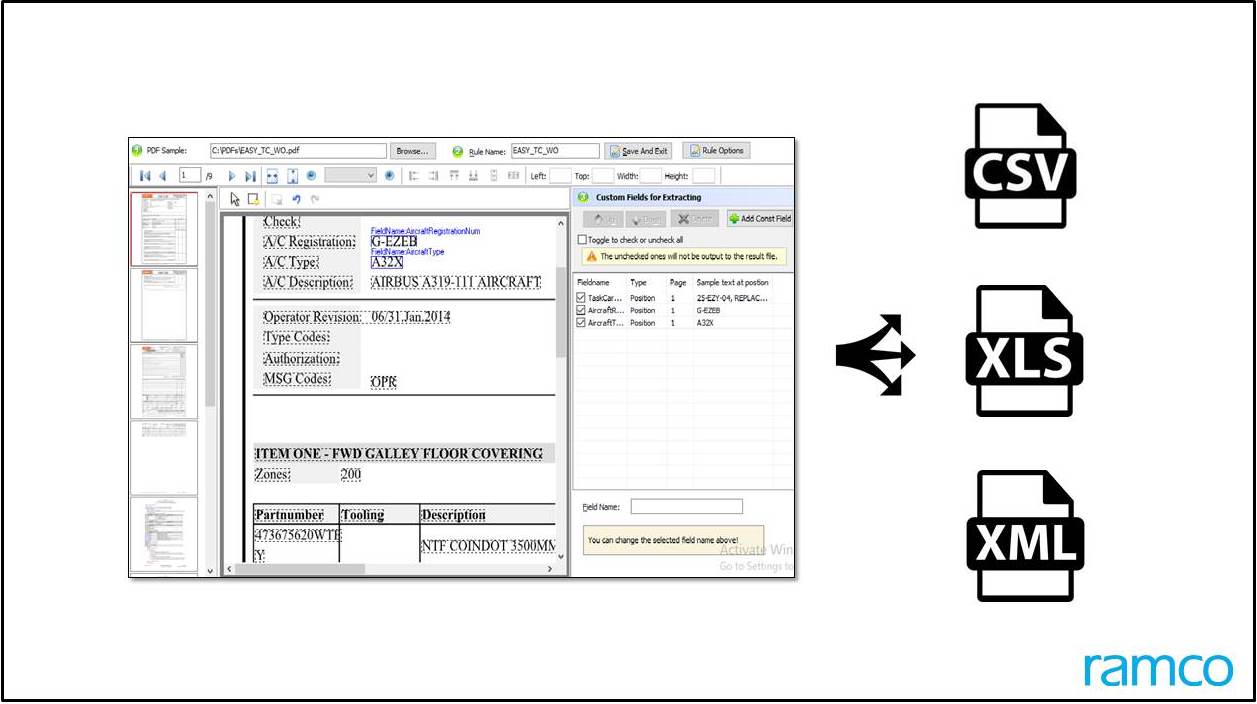

Not all the information you need is available in the tally or summary sheet. It needs to be extracted from the PDF task cards. This extraction step helps in extracting specific data items within the MRO task cards that you would like to convert into the desired output format, which is normally .XLS, .XML, or .CSV.

Similar to split rules, a user-friendly interface to identify the data items on the customer task cards and leveraging advanced tools to extract, reduces the time to mine and upload the data.

Standard data items like MPD number, MPD manhours, skill code, part requirements, and tool requirements are commonly configured for extraction which is leveraged extensively during the next transformation process.

The efficiency of extraction depends on the quality of the PDF. However, manual intervention is needed when dealing with scanned PDF or any exceptions concerning labeling due to which the extraction can fail.

Step 3: TRANSFORM extracted data to gain insights

Extracted data from the task card is often compared to the existing task library to gain insights and to plan the next set of actions. As MRO deals with multiple customers, it is common that you may have an own internal task card linked to the OEM task cards (MPD/AMM) references. The first set of insights is obtained by comparing the customer task card number and identifying the equivalent internal task cards to derive the actual manhours and elapsed time. This insight is valuable during the pre-contracting stage for quoting and useful for the post-contracting stage for manpower planning.

The entire task list is processed in bulk, and the system automatically classifies for further processing. The below table provides parameters for the comparison (between the customer task and internal task library) and classifiers.

| Classifiers | Comparison Parameters and Rules |

| Existing | Customer task OEM reference and internal task OEM reference matches and there is no difference in revision number |

| Revised | Customer task OEM reference and internal task OEM reference matches but a difference in revision number or suffix is observed |

| Suggested | No direct match between Customer task OEM reference and internal task OEM reference, however a match is observed among task description (Same Aircraft Type effectivity). This process relies on historical data and leverages machine learning algorithms. |

| New | No match after considering the above rules |

New aviation task cards related to SB/AD (Service Bulletins / Airworthiness Directive), which do not have a baseline reference, need user intervention to collect standard manhours from external sources and applying the MRO factor to arrive at the planned manhours.

Part lists are also compared with the existing part library and new part number which needs to be created are listed separately. This creation process is semi-automated as it requires additional data both from intelligent defaults and users.

This final step of uploading data completes the setting up of data in the Ramco Aviation solution platform. The new task list identified in the transformation phase (step number 3) is created in the task library and routed for any approval requirement. New part number is created in part master and activated based on the approval profiles.

Task list with its associated task cards is set up under work package number for downstream planning and scheduling stages. Non-routine manhours and part requirements are estimated for the planned tasks by leveraging historical data and machine learning algorithms. Task list can be configured for printing the bar codes.

If the MRO chooses to retain the existing legacy system, the output of the upload process can be interfaced through electronic data exchange.

Paperless operations: Are we there yet?

Managing paper in either physical or PDF format induces inefficiency in the maintenance program. Due to the interdependencies of OEM, airline, and MRO aviation, especially in accessing the right documents, a completely paperless process can be achieved only through the standardization of processes and seamless access amongst the stakeholders.

Also Read: All That You Need to Know About Aviation MROs

This may not be far away, but till that time there’s a critical need to build resilience into your systems to handle and digitize PDF-based process.

That brings us to the end of this blog on MRO task card digitization. For any further clarifications you can reach out to us at contact@ramco.com. You will also find more relevant information from our recent webinar on Digital Transformation, which can be accessed here.

All Rights Reserved. © Copyright 2023. Ramco Systems.