Cement is one of the greatest inventions of humankind. The sector is growing in terms of consumption as well as production – one complementing the other. It has become indispensable to the growth of several other industries. The spurt in urbanization leading to the development of real estate and infrastructure, which in turn has increased construction activities, has resulted in the growth of the cement industry. This growth has been supported by ERP solutions specifically designed for the cement industry.

World over, there’s a demand for cement, and countries are trying their best to manufacture or export cement. Here’s a snapshot of world cement production:

.png?width=311&name=MicrosoftTeams-image%20(6).png)

Source: Cement: 2020 World Market Review and Forecast to 2029 report

China is undoubtedly a leader in cement production, evident from the fact that it supplies cement to more than 50% of the global market. The second-largest manufacturer is India. Other parts of the world are catching up and the industry, overall, is on a growth trajectory. But to grow, the cement industry has to overcome obstacles. Chief among them are the following three challenges:

- Energy-intensive: Manufacturing cement takes a lot of energy, and not just the metaphorical one. It consumes a lot of thermal and electrical energy among others for the process. The processes have to be streamlined and monitored to make it more energy-efficient. he processes have to be streamlined and monitored to make it more energy-efficient. This is where ERP for the cement industry comes into play.

- High attrition of quality manpower: With better opportunities in other verticals of the manufacturing sector (complementing the cement segment), and the challenging nature of the industry's niche skill requirements, the cement industry has been witnessing attrition of quality manpower. ERP solutions can help manage human resources more effectively.

- Handling solids: The greatest challenge for any industry is handling solids throughout the various processes of manufacturing. If not consistent throughout the process flow, it leads to variations in the quality. ERP for the cement industry can help manage this process more efficiently.

The solution to these problems lies in making use of new disruptive technologies such as ERP for the cement industry and ERP solutions.

Some of the best cement plants in the world have already adopted these new technologies that will help them overcome the above challenges, besides facilitating basic process control systems (BPCS) to efficiently supervise the facility and handle process control.

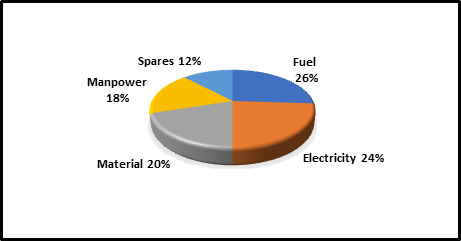

Energy-intensive cement manufacturing

In a typical cement plant, the cost incurred on energy (including thermal and electrical) would amount to around 50 to 60% of the total production cost. Here’s a snapshot of the cost incurred on resources, for a popular cement plant, that confirms our statement:

The power of the Artificial intelligence (AI) platform can be deployed here to optimize the cement-making process, by ensuring smooth operation at every level. The real value of AI is realized only when the implementation team has adequate knowledge and experience in implementing solutions for cement companies. This is what translates the AI experience into an organizational strategy fulfilling most of the organizations’ core vision statement, “To produce high-quality cement at a very optimal cost.” Data science and data analytics is paving the way for artificial intelligence (AI), the technology that has found takers in the cement industry.

ERP solutions can also play a significant role in this context, providing a comprehensive system to manage and streamline the company’s operations. The implementation of ERP for the cement industry can significantly improve the efficiency and productivity of the cement manufacturing process.

AI learns patterns and detects anomalies previously invisible to the user, giving greater insights into process control and automation. The key benefits gained out of the AI-based advanced process control yields great results. Overall improved efficiency can be achieved by:

- Predictive controls for key closed loops: Proactive controls act before the damage is done, as well as result in savings. This can be further enhanced with the use of ERP solutions.

- Planning process flow for solids: When you have access to the past data, you will better understand the procurement patterns and flow of materials and take appropriate decisions that will lead to consistency in process and better quality of output. An ERP for the cement industry can provide valuable insights in this area.

- Reduced energy consumption: Plant-wide automation, along with other AI-driven processes will help in optimizing resources and processes, leading to stabilized and more holistic operations, that will pave way for achieving less energy consumption. ERP solutions can play a significant role in achieving this.

- Less equipment downtime: Unwanted tripping of the main equipment can be avoided with the help of Advanced Process Control (APC), an intelligent way to control untimely downtime due to asset failure. ERP for the cement industry can help manage this process more efficiently.

- Data visibility: With easy-to-understand, real-time information at one’s fingertips, decision-makers or plant managers can make more informed & actionable decisions at an organizational or operational level. ERP solutions can provide this data visibility. Planning: Planning should be in a way that can be updated in real-time. And a solution should enable maintenance schedules to be precisely timed. ERP for the cement industry is designed to handle this.

- Planning: Planning should be in a way that can be updated in real-time. And a solution should enable maintenance schedules to be precisely timed

Look for a solution that will help run your cement business efficiently. Ramco ERP for cement manufacturers helped a major cement group, who used the Advance Process Control solutions, reap the following benefits:

- Productivity increase up to 1 %

- Specific Power saving up to 2 %

- Specific heat saving up to 1 %

And do not be misled by the small percentages, for even an infinitesimal change in the cement business means unbelievably, huge savings.

The return on investment (RoI) is phenomenal when you look to transform your cement company with digital transformation initiatives. And this may be like one small step towards cement plant digital transformation, but a giant leap towards building a connected organization. ERP solutions for the cement industry can play a significant role in this transformation, providing a comprehensive system to manage and streamline the company’s operations. The implementation of ERP for the cement industry can significantly improve the efficiency and productivity of the cement manufacturing process.

Related Posts